In the first year of the project, collaborations among Enabling partners and its stakeholders have been very promising!

During the 2nd edition Science Festival Fermhamente*, held in Fermo last October 2018, Itabia and Stiftinga Vestlandsforsking / Western Norway Research Institute (WNRI) had the opportunity to participate in the conference “Rural and agri-industrial wastes: Valorization in new and innovative products”. The conference was organized by ITT Montani di Fermo an active stakeholder of the Enabling project, in close collaboration with Fermo's Municipality.

The basic idea behind this multi-party conference was to present the recent progress achieved in the scientific field of replacing fossil fuels use in the manufacture of products, such as plastics. The use of rural and agro-industrial residues, as key-ingredients for producing Biobased products, was the central focus.

WNRI has performed a detailed analysis of rural and agro-industrial wastes from Western Norway and their potentials for use in production bio-based products.

Itabia has highlighted several European Good Practices focused on virtuous use of agricultural wastes in several innovative supply chains, from bioplastics to tires, and finally to producing biofertilizers.

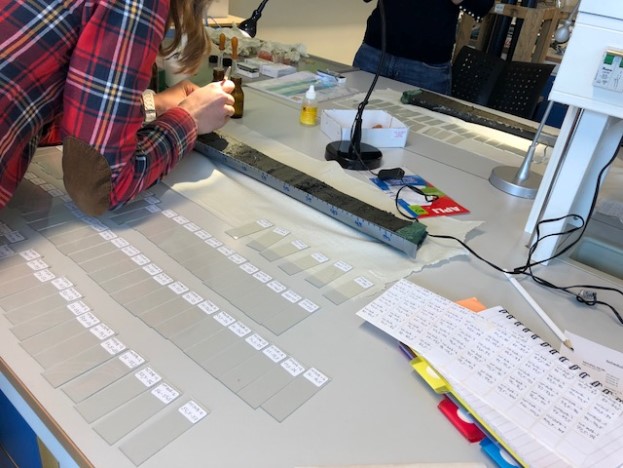

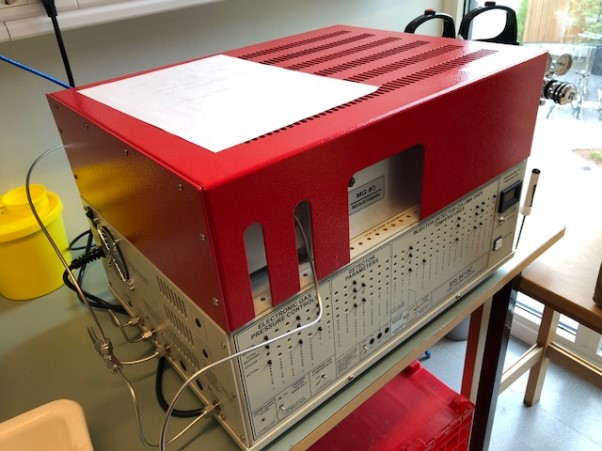

The ITT Montani Institute has shared the latest progress on fossil-based plastics substitution via upcycling of the food industry to produce new composites. More in depth, they showed their concrete experiences derived from numerous laboratory experiments focused on valorizing of agro-industrial and fishing residuals towards the sustainable production of new bio-materials. ITT Montani has also analyzed the molecular fingerprint of the composites volatiles in order to demonstrate that the priority air pollutants released by fossil plastics that pose a significant public health threat are missing.

The issues addressed are in line with latest emerging political concept on circular bio-economy. The exploitation of residual wastes towards sustainable production in biodegradable biomaterials, integrated with the new concept of biorefineries, reduces the enormous environmental impact caused by the accumulation of non-biodegradable wastes, globally. This leads to avoidance of higher costs of waste disposal. At the same time, it avoids using food resources as a starting material for bio-based composites, and results in a non-food bio-based output that can be integrated with several common steps of the circular economy (bio-fuels or bio-energy pathways).

Thanks to sharing of mentioned experiences, concrete examples of which opportunities can have innovative biomaterials, what impact will have on society behaviour and potential opportunities of job and economic growth, have been presented.

Enabling Partners : Dr. Otto Andersen and Dr. Hønsi, Torunn (WNRI), Dr. Carla de Carolis (ITABIA)

Benerficiaries from ITT Montani Fermo: Prof. Teresa Cecchi and Headmaster Dr. Margherita Bonanni (ITT Montani)

* https://www.comune.fermo.it/it/ElencoAttivitaFermhamente2018-UFFICIALE-pdf/ ; https://www.comune.fermo.it/it/fermhamente/